Cart 0 Product Products (empty)

No products

To be determined Shipping

0,00 zł Total

Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart. There is 1 item in your cart.

Total products

Total shipping To be determined

Total

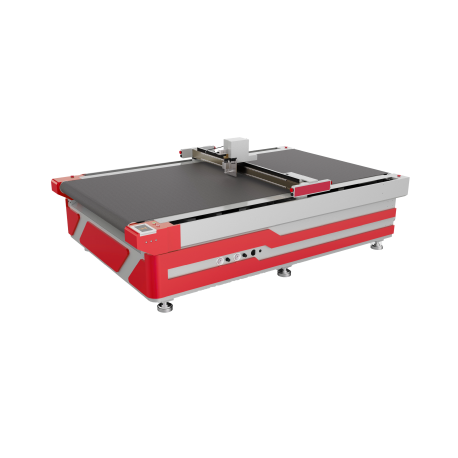

ULTIMA UL-C1825 Single-Layer Cutter

New product

The UL-C1825 is an advanced automatic cutting machine designed to meet the highest industrial requirements. Thanks to its wide range of applications, the UL-C1825 is the...

The UL-C1825 is an advanced automatic cutting machine designed to meet the highest industrial requirements.

Thanks to its wide range of applications, the UL-C1825 is the ideal solution for companies processing various materials, from fabric, foam, cardboard, leather, PVC, to composite sheets.

Standard Functions

- Cast Steel Table: With automatic material feeding function.

- Material Feeding System: Automatic feeding system with rollers and an emergency stop switch.

- High-Frequency Servo Motors: Delta servo motors.

- Vacuum Pump: 9kW vacuum pump with a silencer.

- Control System: Advanced controller with USB and Ethernet ports.

- Linear Guides: PMI linear guides for precise movement.

- Boke Intelligence Software: Auto-nesting system for cutting optimization.

- Standard Equipment and Accessories

- Rotary Knife: Designed for cutting difficult, fibrous materials such as fiberglass, aramid, and thin fabrics.

- V-Cut Tool: Excellent for creating complex patterns from composite materials, with the ability to cut at 5 different angles (0°, 15°, 22.5°, 30°, 45°).

- Pneumatic Oscillating Knife: Air-powered tool, ideal for cutting hard, dense materials, but also capable of handling soft, thicker materials like foam.

- Punching Tool: For making holes of the same diameter in soft materials (standard diameters 2mm/4mm/6mm).

- Milling Tool: Mainly for hard materials such as acrylic, aluminum plates, MDF, and others.

- CCD Camera: Industrial CCD camera for collecting material information (patterns and shapes), used for quick and precise cutting of irregular materials.

- Projector: For projecting cutting graphics, allowing for the adjustment of cutting positions according to the projection, enabling quick and precise cutting.

- Marker Holder: For marking and drawing descriptions or numbers on the material.

Technical parameters:

- Maximum Cutting Speed: 1200 mm/s (depending on the material)

- Maximum Movement Speed: 1500 mm/s

- Working Area: 1800x2500 mm (C1825), 1600x2500 mm (C1625)

- Compatible Tools: Rotary knife, oscillating knife, drag knife, marker

- Turbine Power: 9 kW

- Application: Leather, fabric, PVC, cardboard, and others

- Maximum Cutting Thickness: 20 mm depending on the material

- Material Fixation Method: Vacuum absorption

- Repositioning Accuracy: ± 0.05 mm

- Mechanical Accuracy: Max. 0.05 mm

- Drive System: Servo motor

- Control System: RD controller

- Data Transmission Method: USB / Ethernet

- Supported File Formats: DXF, PLT, AI, SVG, PDF, NC, DST, DSB, etc.

- Operating Environment: Temperature 0-40°C, humidity 20-80% RH

- Power Supply and Total Power: 400V / 50 Hz - 11 kW